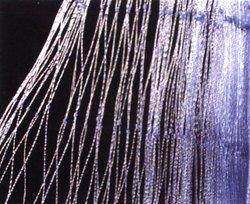

Multi-Strand Monofilament Nylon

Multi-Strand Monofilament netting is constructed from two or more individual strands of monofilament twisted together to form a single twine. The twine is then manufactured into netting. Multi-strand monofilament nylon is:

- Nearly transparent in water and can be tinted (dyed) most any color.

- Most commonly used in gill and trammel nets.

- Softer and more flexible than single-strand monofilament netting. It is more compact and will not use as much space to store.

- Stronger than equal diameters of single-strand monofilament.

- Multi-strand monofilament is normally more expensive than single-strand monofilament.

- Debris (sticks, grass, etc.) is more difficult to remove from multi-strand monofilament than from single-strand monofilament.

- Available in single, double, or triple knots.

- Available in depthways stretched (most common) or lengthways stretched.

- Thicker or heavier selvedges (for added strength) are available as well as multifilament selvedges.

- Fitec’s monofilament netting is made from high-quality, virgin resin with excellent tensile (breaking) strength. All Fitec monofilament netting is heat-set in a controlled chamber to provide tight knots that will not slip under pressure. Our factory is state-of-the-art with stringent quality control. This ensures consistent mesh and twine sizes throughout the netting. Fitec’s monofilament netting factory manufactures a wide range of twine sizes in most any mesh size, mesh deep, or color.

| Multi-Strand Monofilament Nylon Netting | |||||||

| (Red De Multi-Monofilamento) | |||||||

| Approximate | |||||||

| MM Dia x Ply | Japanese | USA | Tensile(Breaking) Strength | ||||

| Size x Ply | Number | of Twine | |||||

| Pounds | Kilos | ||||||

| (Libras) | (Kilos) | ||||||

| .20mm x 4 | 1.5 x 4 | #139 | 21.16 | 9.6 | |||

| .20mm x 5 | 1.5 x 5 | n/a | 26.46 | 12 | |||

| .20mm x 6 | 1.5 x 6 | n/a | 31.75 | 14.4 | |||

| .20mm x 8 | 1.5 x 8 | #277 | 42.34 | 19.2 | |||

| .20mm x 10 | 1.5 x 10 | n/a | 52.7 | 23.9 | |||

| .20mm x 12 | 1.5 x 12 | #7 | 63.28 | 28.7 | |||

| .20mm x 14 | 1.5 x 14 | n/a | 73.87 | 33.5 | |||

| .20mm x 16 | 1.5 x 16 | #9 | 83.79 | 38 | |||

| Note: | The specifications listed are for commonly accepted industry applications. | ||||||

| We can custom manufacture to your specifications- contact us for details | |||||||