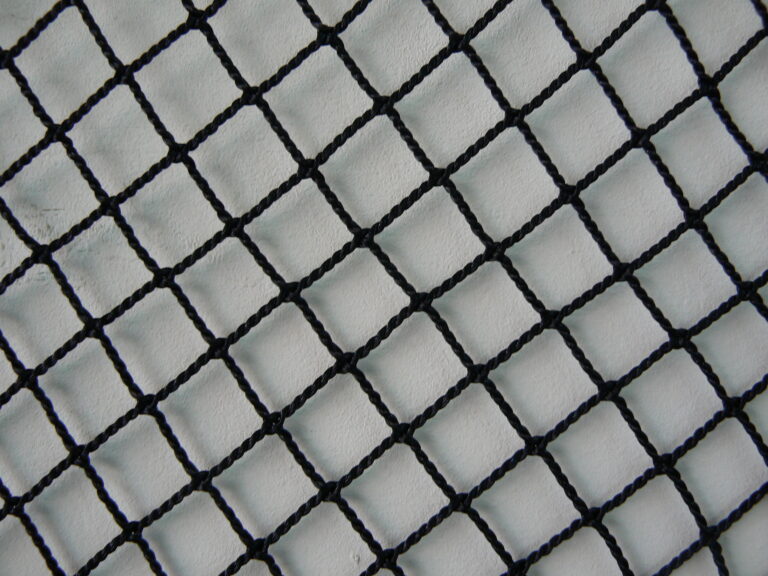

Ultra High Molecular Weight Polyethylene (UHMWP) Twisted Knotless

Ultra High Molecular Weight Polyethylene (UHMWPE) is a high performance fiber used in many applications- fish netting, rope, personal armor, vehicle armor, cut resistant gloves etc. Some of the primary characteristics of UHMWPE are:

- Exceptional weight to strength ratio- UHMWPE is 15 times stronger pound for pound than steel. Because of the very high tensile(breaking) strength, the diameters of the twines used to make netting can be much smaller than with more commonly used fibers. The smaller diameters are more hydrodynamic ( less water resistance) when pulled through water and thereby have significant fuel savings.

- UHMWPE stretches very little under pressure and is ideal for applications where elasticity is not desirable

- UHMWPE will not absorb water and will float on the surface

- Ultra High Molecular Weight Polyethylene is a soft fiber that is not stiff or rough to the touch

- The cost per pound or kilo of UHMWPE is much higher than other commonly used fibers e. traditional polyethylene, polypropylene, or nylon

- UHMWPE can be made into twisted, braided or raschel netting

Fitec’s Ultra High Molecular Weight Polyethylene (UHMWPE) netting is made from high quality, virgin resin with exceptional tensile (breaking) strength. All UHMWPE is heatset to provide tight knots that resist slipping under pressure. Our factory is state of the art with stringent quality control which ensures consistent mesh and twine sizes throughout the netting. Fitec’s UHMWPE factory manufacturers a wide range of twine sizes in most any mesh size and meshes deep. A variety of coatings are available for added abrasion resistance and knot holding ability.

| Twisted Knotless Ultra High Molecular Weight Polyetylene Netting ( UHWMPE) | |||||

| (Twisted Sin Nudos Ultra Red De Polietileno De Alto Peso Molecular (UHMWPE)) | |||||

| Twine | Denier and | Tensile Strength | Tensile Strength | Stretch Mesh | Meshes |

| Size | Number of Plys | Pounds | Kilograms | Sizes Available | Deep Available |

| 0.90mm | 1,500 x 2 | 119 | 53.9 | 3/4 inch (19mm) and up | 1 to 50 or 100 or 200 |

| 0.95mm | 1,600 x 2 | 127 | 57.6 | 3/4 inch (19mm) and up | 1 to 50 or 100 or 200 |

| 1.05mm | 1,000 x 4 | 159 | 72.1 | 3/4 inch (19mm) and up | 1 to 50 or 100 or 200 |

| 1.15mm | 1,200 x 4 | 214.0 | 97 | 3/4 inch (19mm) and up | 1 to 50 or 100 or 200 |

| 1.3mm | 1,500 x 4 | 238 | 107.9 | 3/4 inch (19mm) and up | 1 to 50 or 100 or 200 |

| 1.35mm | 1,600 x 4 | 254.0 | 115.2 | 3/4 inch (19mm) and up | 1 to 50 or 100 or 200 |

| Note: | The specifications listed are for commonly accepted industry applications. | ||||

| We can custom manufacture to your specifications- contact us for details | |||||