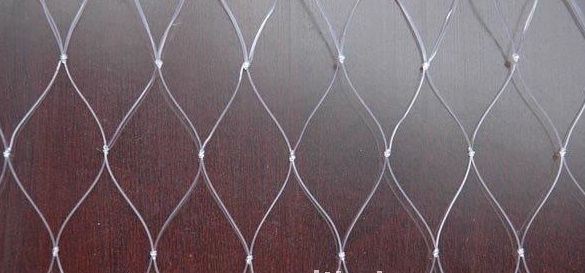

Single Strand Monofilament Nylon

Monofilament nylon netting is primarily used in gill nets and trammel nets. The netting is made from line similar to the type of line used in rod and reel fishing. Fishermen worldwide can attest to the effectiveness of Fitec monofilament netting, and it is used in fisheries all over the globe. There are several advantages to using monofilament netting:

- Monofilament is almost transparent and is harder for fish to see in clear water, or it can be tinted (dyed) almost any color to match the color of the water where the netting will be fished.

- Easy to clean debris (sticks, grass etc.) from.

- Abrasion resistant.

- Absorbs very little water.

- Available in single, double (most common), U, and triple knot.

- Available with heavier or thicker selvedges for added strength. Multifilament selvedges are also available.

- Can be stretched depthways (most common) or lengthways.

Fitec’s monofilament netting is made from high-quality, virgin resin with excellent tensile (breaking) strength. All Fitec monofilament netting is heat-set in a controlled chamber to provide tight knots that will not slip under pressure. Our factory is state-of-the-art with stringent quality control. This ensures consistent mesh and twine sizes throughout the netting. Fitec’s monofilament netting factory manufactures a wide range of twine sizes in most any mesh size, meshes deep, or color.

| Monofilament Nylon Single Strand Specifications | |||||||

| (Red De Monofilamento) | |||||||

| Twine Tensile | |||||||

| Diameter | Japanese | USA | Approx Breaking Test | ||||

| (mm) | Size | Size | Pounds | Kilos | |||

| 0.15 | 0.8 | n/a | 2.90 | 1.31 | |||

| 0.18 | n/a | n/a | 3.77 | 1.71 | |||

| 0.20 | 1.5 | 110/3 | 4.88 | 2.21 | |||

| 0.23 | 2 | 210/2 | 5.95 | 2.70 | |||

| 0.25 | 2.5 | n/a | 6.95 | 3.15 | |||

| 0.27 | n/a | n/a | 8.53 | 3.87 | |||

| 0.28 | 3 | #69 | 8.53 | 3.87 | |||

| 0.30 | 3.5 | n/a | 9.72 | 4.41 | |||

| 0.33 | 4 | #104 | 11.59 | 5.26 | |||

| 0.35 | 4.5 | n/a | 12.90 | 5.85 | |||

| 0.37 | 5 | n/a | 14.13 | 6.41 | |||

| 0.40 | 6 | #139 | 16.27 | 7.38 | |||

| 0.45 | 7.5 | n/a | 20.24 | 9.18 | |||

| 0.47 | 8 | #177 | 21.68 | 9.83 | |||

| 0.50 | 9 | n/a | 24.21 | 10.98 | |||

| 0.52 | 10 | #208 | 25.31 | 11.48 | |||

| 0.55 | 11 | n/a | 28.07 | 12.73 | |||

| 0.57 | 12 | #277 | 29.77 | 13.50 | |||

| 0.60 | n/a | n/a | 32.94 | 14.94 | |||

| 0.62 | 14 | #6 | 34.73 | 15.75 | |||

| 0.65 | n/a | n/a | 36.71 | 16.65 | |||

| 0.70 | 18 | #7 | 39.69 | 18.00 | |||

| 0.75 | n/a | n/a | 45.25 | 20.52 | |||

| 0.80 | 24 | #9 | 49.61 | 22.50 | |||

| 0.85 | n/a | n/a | 53.58 | 24.30 | |||

| 0.90 | 30 | #12 | 57.55 | 26.10 | |||

| 0.95 | n/a | n/a | 67.87 | 30.78 | |||

| 1.05 | 40 | #15 | 67.87 | 30.78 | |||

| Note: | The specifications listed are for commonly accepted industry applications. | ||||||

| We can custom manufacture to your specifications- contact us for details | |||||||