What is a Mesh?

A mesh is the hole in the netting that is formed when four strands of twine are knotted or knitted together. The shape of the mesh is normally diamond-shaped or square-shaped. (See Image Below)

How Do I Measure the Size of the Mesh (Hole) in Netting?

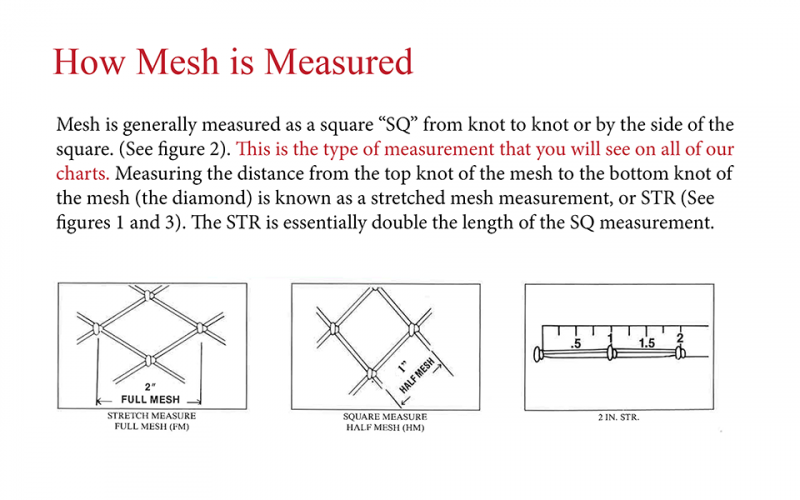

Mesh size is the measurement of the hole or opening in netting. Netting is measured in several ways, so it is very important that both the manufacturer and the end user of the netting measure the mesh size using the same method. Netting is measured by:

- Stretch or Full Measurement The stretch or full measurement can be measured by one of 3 methods:

a) Center of one knot to the center of the next knot (CC)

b) Inside one knot to the outside of the next knot

c) Inside of one knot to the inside of the next knot (IK)

2. Square or Half Measurement

3. Netting can be measured depthways (perpendicular to the selvedges) or it can be measured lengthways (parallel to the selvedges). The measurement of the mesh in knotted netting will be slightly larger if measured depthways (perpendicular to the selvedges)

4. When measuring meshes, normally three to six meshes are measured at one time then divided by the number of meshes measured to calculate the average mesh size.

A typical method of measurement would be:

Example: Six stretch or full meshes pulled tightly measures 12 inches in the depthways direction, therefore each mesh will be 2 inches stretch or full mesh.

What Are Meshes Deep?

Meshes deep will determine the height (top to bottom) of a piece of netting. Meshes deep is the number of stretch or full meshes from the top of the netting to the bottom of the netting (between the selvedges). Example: 50 meshes deep of 2 inch stretch or full measure pulled tightly will be 100 inches deep from top to bottom.

What Are Meshes Long?

Meshes long will determine the length (left to right) of a piece of netting. Meshes long is the number of stretch or full meshes beginning at the left edge and ending at the right edge of a piece of netting (parallel to the selvedges). Example: 2,000 meshes long of 2 inch stretch or full measure pulled tightly will be 4,000 inches long from left to right.

What Does Twine Size Mean?

Twine size refers to the diameter (thickness) of the twine or string that forms the mesh in netting. There are several different measuring systems to measure the same piece of twine. Below are four of the most common methods used to measure the diameter of the same piece of twine:

- Denier System= 210d/192(64×3)

- Fraction of an inch system= 1/8 inch

- Millimeters = 3.17mm

- American numbering system = #72

What are Selvedges?

Selvedges are smooth, finished edges made of twine that run the full length (left to right) of a piece of netting. Selvedges are created in the manufacturing process and can be single (one piece) or double (two pieces of twine). Selvedges can have a larger stretch or full mesh size ( see stretch mesh above) than the rest of the netting. Selvedges can also be manufactured with larger twine size diameters (see twine size above) than the rest of the netting. Finally, selvedges can be made of a different material than the rest of the netting.

What are Netting Treatments?

Nylon, one of the most common fibers used in netting, is normally dipped into a light solution of resin or bond which minimizes knot slippage under pressure. Depending on the use of the netting, additional treatment of netting may be desirable. Some common treatments are:

- Dyeing the netting to change the color from white to most any other color

- Net Dips: Netting is submerged into a solution similar to paint which coats the netting giving it an increased abrasion resistance and additional protection from UV damage. Net dip (Fitec brand “Tuff Kote”) will dry to a smooth, non-sticky finish, with rich, color.

- Tar: A treatment used primarily in fishing where netting is submerged in a “tar” similar to asphalt tar used in roads. The netting will dry to a slight tacky or sticky finish and will often rub onto other surfaces.

Note: Usually only nylon or polyester will have netting treatment. Polyethylene fiber will not absorb liquids, and dyeing or netting treatments will not adhere to the surface of polyethylene very well.

Which Netting Construction is Better – Knotted or Knotless?

Knotted and knotless netting are both widely used for many different applications. Each has advantages and disadvantages, and the use of the netting will determine which construction is best for your application.

- Knotted netting has been used for thousands of years and is the most common netting construction. Knotted netting is usually more readily available.

- It is easier to repair than knotless netting

- Generally, knotted netting is less expensive per pound or kilo than knotless netting

- The twine in knotted netting is usually tighter and harder than knotless netting and debris such as sticks, burrs, etc. tends to not stick to knotted netting as quickly as they do to knotless netting

- Knotless construction has a smoother finish and feel (since there are no knots) and is normally softer than knotted netting

- Since there are no knots, knotless netting has a greater yield (more square feet per pound) than knotted netting

- Knotless netting can be manufactured in very deep or wide strips

- Knotless netting is more difficult to repair than knotted netting

Which is Better – Twisted or Braided Knotted Netting?

Twisted knotted netting and braided knotted netting each have their own advantages and disadvantages:

Twisted Knotted Netting

- Most common knotted construction

- Stronger tensile (breaking) strength than braided knotted construction

- Less expensive per pound or kilo than braided

- Not as abrasion-resistant as braided construction and will wear out or chaff quickly if pulled through sand or rocks

- Tends to absorb more sand, dirt, and debris than braided knotted

- Easier to repair than braided construction

Braided Knotted Netting

- Very abrasion-resistant and will not wear out as quickly as twisted knotted netting when pulled through sand or rubbing against rocks

- The construction of braided twine can be altered to achieve higher tensile (break) strength, abrasion-resistance, or to change the weight

- Is normally more expensive per pound or kilo than twisted construction

- More difficult to repair than twisted construction

Which Fiber is Best – Nylon or Polyethylene?

Nylon and Polyethylene are the two most common fibers used in netting. Both have advantages and disadvantages:

- Nylon fiber has been in common use longer than polyethylene

- Nylon fiber is elastic and will stretch (up to a point) before it breaks

- Nylon is stronger and has a higher tensile (breaking) strength than common polyethylene fiber

- Nylon will sink in water and will not float

- Untreated nylon netting is softer and less stiff or rigid than polyethylene

- Nylon is usually more expensive per pound or kilo than polyethylene

- Nylon is usually manufactured (extruded) a white color and must be dyed if a different color is desired

- Various netting treatments (bonding, dips, tar, etc.) will adhere to nylon fiber well

- Polyethylene (also known as Poly) is not elastic and will stretch very little before it breaks

- Commonly used polyethylene fiber is not as strong as nylon and has a lower tensile (breaking) strength. Note: there are Ultra High Molecular Weight Polyethylene fibers that are very strong and very expensive.

- Polyethylene will float on the surface of the water and will not sink

- Commonly used polyethylene fiber is less expensive per pound or kilo than nylon

- Color is added to polyethylene resin and does not need to be dyed. Once the fiber is made, the color cannot be changed and netting treatments do not adhere to the surface of polyethylene very well.

- Because the fibers in polyethylene are larger in diameter or size than fibers in nylon, polyethylene is more abrasion-resistant but is stiffer or more rigid than untreated nylon